Tension Monitoring in Extrusion

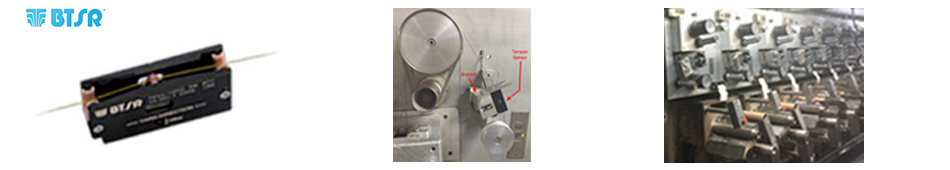

The BTSR tension monitoring system, consisting of a touchscreen control terminal and TS55 series programmable sensors, represents the BTSR solution for tension measurement and monitoring of a yarn put under control in the course of a textile process.

This product has been designed for applications on yarn preparation processes which require accurate monitoring & control of yarn quality. This is made possible by the use of TS55 (Tension Smart Scanning Sensor) device, capable of performing an exact measurement and analysis of the yarn tension.

High accuracy and repeatability are assured by the exclusive digital technology (Digital Signal Processor) developed by BTSR, based upon the use of a loading cell which converts the tension exerted by the yarn into a digital signal.

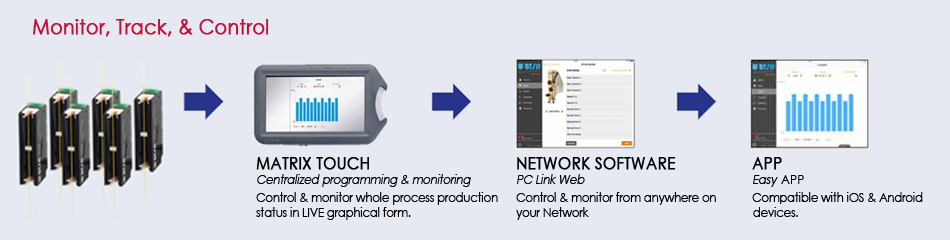

The Touch Matrix control terminal, combined with the TS55 devices installed along the process, provides advanced programming functions. You can program the rated tension of the yarn, as well as the maximum and minimum tensions beyond which the position shall be stopped or signal an alert. Parameters are established with programmable time delays around the average tension, peak high and peak low. Each sensor allows for "recipes/styles" to be easily created with customized settings for multiple types of yarns.

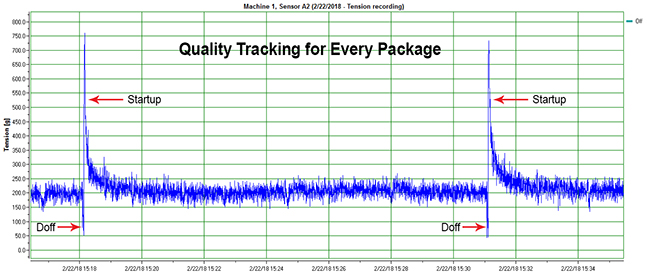

In the past year, we've performed some great analysis in extrusion with tension monitoring. We were able to obtain some great data on how tension monitoring will allow you to identify/catch a large variety of process anomalies & changes. Tension is the derivative by which you can identify & track most all yarn process anomalies. It's the one place you can always look to detect off quality. Below is a list of what we are able to identify, track, & prevent in the extrusion process.

-

Temperature changes in godets can be identified, tracked, & prevented.

-

Wrong number of wraps on godets can be detected, tracked, & prevented.

-

Temperature changes due to quench door being open can be detected, tracked, & prevented.

-

Winder takeoff/ starting acceleration being set to high will cause dramatic tension variation.

-

Changes in content of the raw material can be detected, tracked, & prevented.

-

Spin finish can be monitored because it causes friction variation.

-

Failure points (such as spin pump) throughout the process will cause variation in tension.

-

Tension variation between positions are easily & quickly identified.

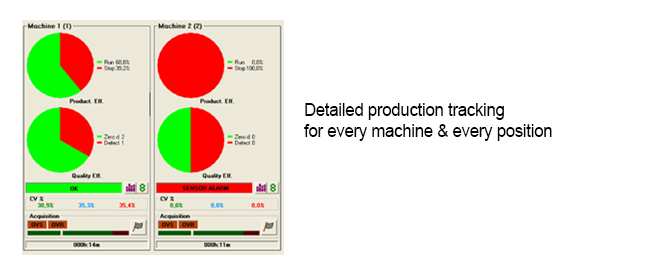

Besides tracking quality, every tension sensor is programmed to track production and can perform as a stop motion device. All start/stop times are monitored live and tracked in detail. For every doff, it gives you a full production record of start/stop times as well as detailed quality information on every anomaly that occurred during the creation of the package.

For more information on the system & trial analysis, please contact us. We would be happy to discuss your needs and setup a trial for you to analyze your own extrusion process.

Additional Info & Videos

Presentation: Tension Monitoring

From extrusion to warping, tension trial data is shown & explained.